Bar Cutting Machine

Monolith Steel Structure- Spartan’s newly launched premium series of Cutting and bending machines in Dubai are designed in a monolith steel structure using the higher thickness of steel plate so the number of welding joints in the body is minimal which ensures better design strength of the body and longer life of the machine.

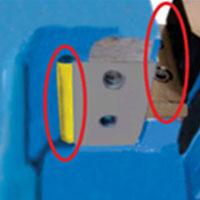

Gearing Arrangement- 2 Stage gear setup to give better torque efficiency thereby reducing the load on cutting blade & increasing the life of cutting blade. the entire cutting process becomes smooth.

Hand Lever Design- The Hand lever design had been made on the push concept with a heavy-duty return spring. So that the operator will have less fatigue, fewer efforts and better efficiency.