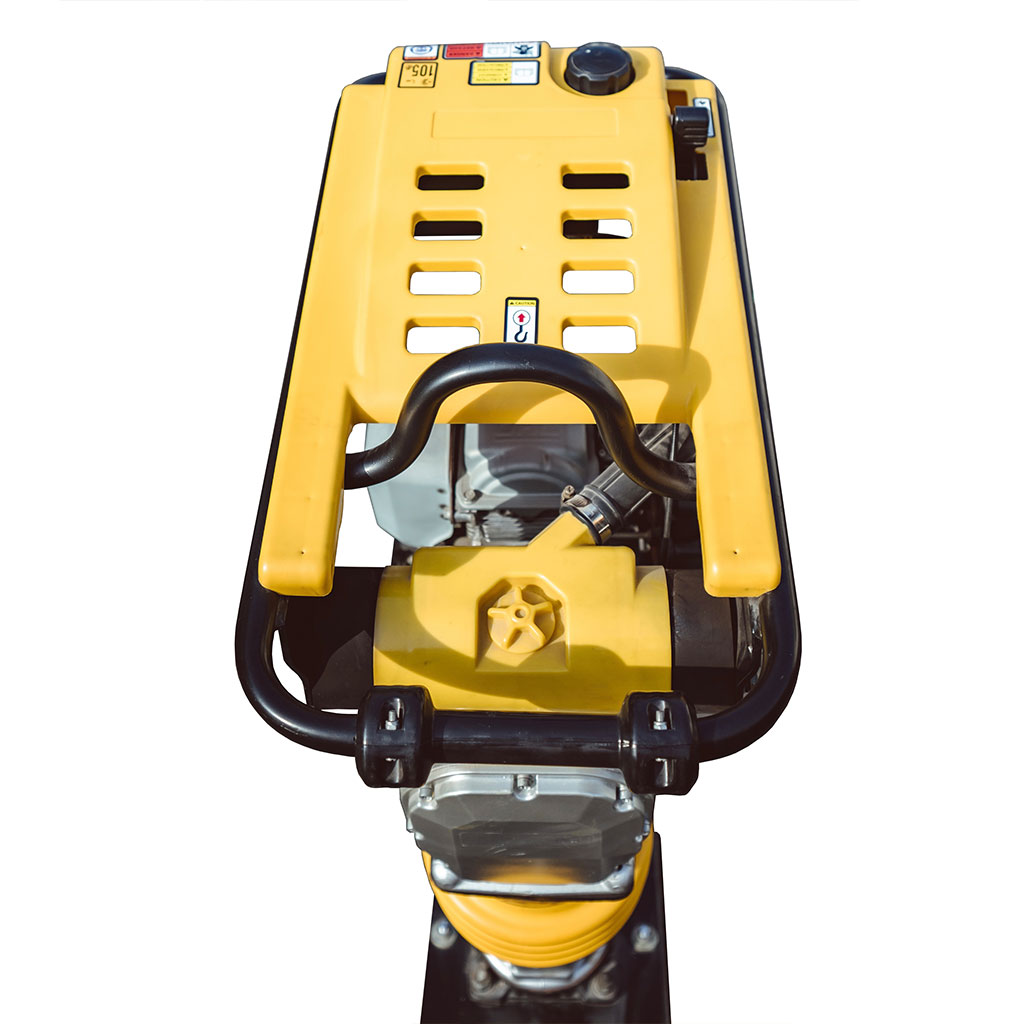

RAMMERS

MBW works continuously to lower maintenance and extend life expectations of its rammers. We now introduce the industry’s first percussion system completely free of high friction/heat/wear metal-on-metal reciprocating wear surfaces. The patent-pending design features c-shaped, non-metallic slide bearings between spring separator and spring box, ram shaft and spring box, and spring box and guide tube. Wear characteristics of the MBW bearings are several times better than traditional steel-on-cast iron designs.

If you’re looking for a trench rammer for sale, MBW offers innovative solutions that combine durability and efficiency to meet your compaction needs. For superior performance in confined spaces, our tamping rammer machine ensures consistent, high-quality results while reducing operating friction and heat.

Lower operating friction/heat provides positive implications for engine, lubricant, and bellows life. In the event percussion system lubricant is lost, MBW percussion systems are designed to fail a single slide bearing, locking up the system and preventing damage to other bearing surfaces, as well as bearings and seals in the rammer’s gearbox. Because MBW percussion systems generate less internal friction, rammers operate more efficiently, consume less fuel, and deliver more compaction force for the purpose intended. When replacement is eventually called for, MBW slide bearings are replaced at low cost, returning percussion systems to original specifications.